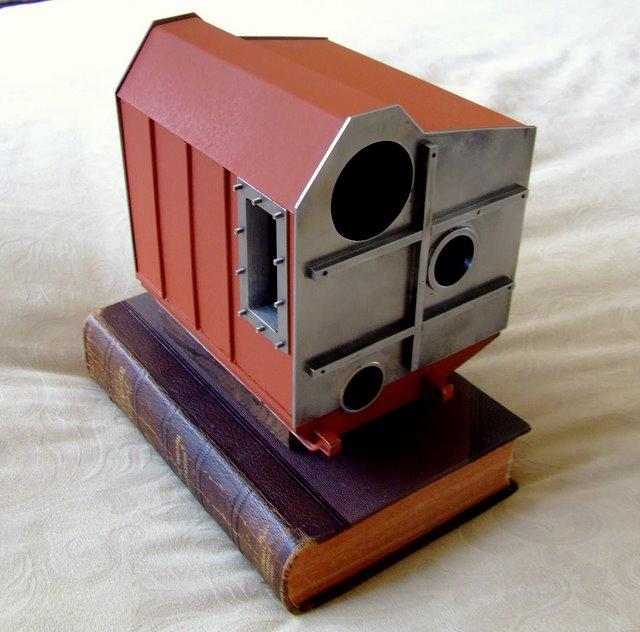

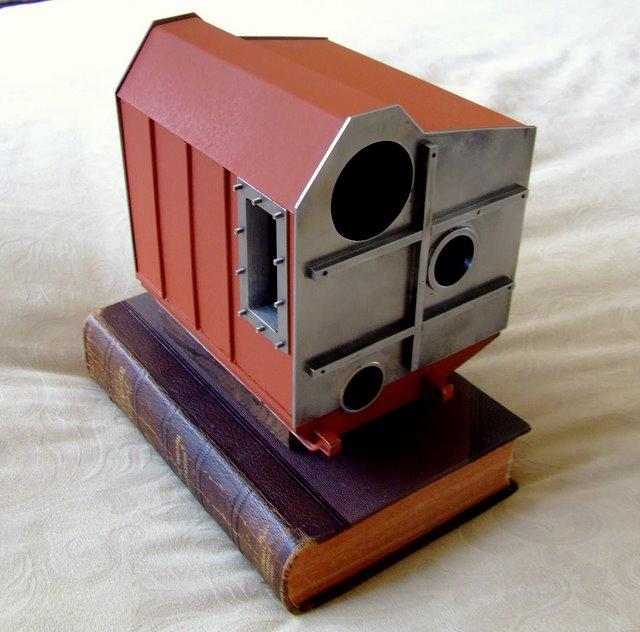

It had progressed to this state prior to starting the

pressure vessel (circa Jan. 25, 2009)

(the front has since been cleaned up)

The red primer is being used as a visual

aid for sanding, etc. prior to final finishing

There is a lot to do before I start any silver brazing on the new

boiler. I have been doing much brainwork in working out the tube layout

- but I have little to work with... The

decisions were taken and I completed drilling the two drums. At least

there is now a hole at every required location - however that is only the

beginning. I have arranged things so that most of the water tubes do not enter

the thick drum walls along radii, but at various angles. This

tubing (1/4" - 24 gauge) cannot take sharp bends without deforming. This is to allow

me to use the largest possible water tubes with thinnest possible walls,

since this arrangement requires the least sharp bending. It is the ideal

tubing for a watertube boiler - very good heat conduction to the water.

Which brings us to the two jobs facing me prior to silver brazing.

First the holes must be made in a shape somewhere between elliptical and

oval. Fortunately, I think I can form them once I determine the exact

entry angle, by introducing a rotating reamer and then twisting the drum slowly

until the required angle is reached. It will not be a good time for

mistakes. The second job of course is to make all the tubes, putting in

the bends where needed, cutting them to length and then re-opening the ends out

to the original size.

A long term concern is for my dwindling supply of heavy-wall copper

pipe in the 50mm to 150mm range. I have some, but not a lot. To buy

it here these days would require having a five metre length shipped from who knows

where - arriving dented after long, careless (and expensive) shipping. The

total cost would be ridiculous. I used to buy it in any length,

over-the-counter in one of several shops here in town.

My progress as of Feb 16/09

Here is how it came

about:

Since the drums required bumped-out heads, I had to remove the

equivalent amount of shell length in order for the completed pressure vessel to fit within the boiler

casing.

Finishing off the drum ends in the Craftex

lathe

The ends had to be square, as I used them for reference

to mark out the tube rows

Punch-marking the lower drum under the Lomo

stereo microscope

Drilling the pilot holes with my new continuously variable speed drill

press

This drill has lots of power

- it breaks through smoothly

Testing the lower drum in situ

in the enclosure

(still part way through the drilling process)

Note that eventually all inside surfaces of the enclosure will

be clad with mirrored aluminium tape

which will have an overlay of 1/2" thick high-temperature

insulating blanket

Inside the (small) mud drum

The small drum

- the drum is much closer so the camera lens causes it to falsely dwarf the boiler

casing!

The larger (upper) steam drum

Masking tape used to lay out each tube row

Under the microscope I marked the positions by hand

with a prick punch

I later used a small hammer on the workbench to tap the punch

harder

(finally the finished dimples to the left of the masking tape have been

expanded with an automatic punch)

LED light

Another check to be sure I wasn't going

astray!

Finally the holes for the steam outlet, two safety

valves and

vent valve were cut on top of the steam

drum

There will be considerable internal structure in this

upper drum

(at this point I am still working out those

details)

A close-up view of the work as of Feb 16,

2009