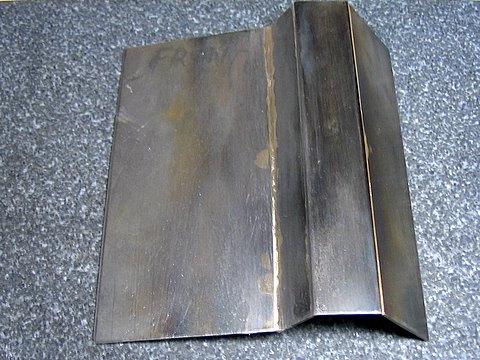

End flanges partially formed

Two ends finished and silver brazed

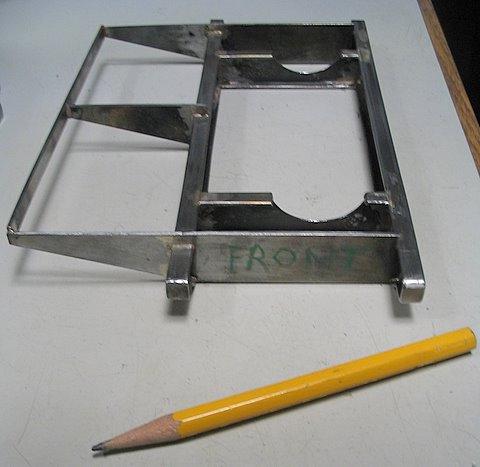

Beginning the assembly of the skid

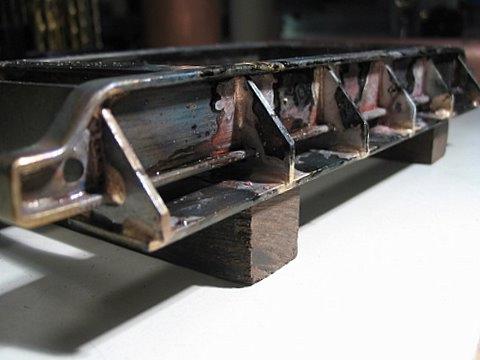

Lots of clean-up and silver

brazing yet to do

A dull pencil is a sign that lots of

work has been going on!

(those are not "rusty spots" but some sporadic copper plating that happened in the pickle solution)

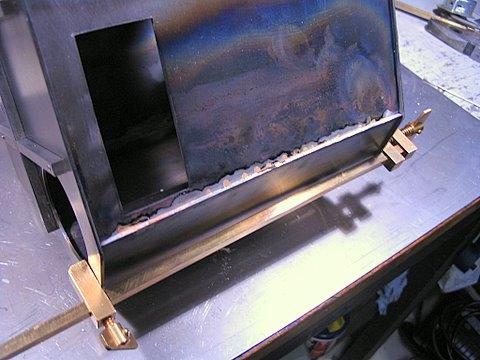

Convection-section floor

with the supporting gusset piece awaiting brazing

The mud drum shell being tested in its eventual position

Cooling off - upside down after silver

brazing

Back into the acid!

Painted in red oxide...the mud drum cradle is

visible here

Note the minimum amount thermal contact surface area between cradle and

drum. I am making every attempt to prevent heat loss from the drums and

tubes. I intend to totally eliminate any metal-to-metal contact between the

boiler and its casing. The casing will be well insulated with

Cerrablanket material.

The finished skid on the bench awaiting flat black

paint

Fitting the front (inside) corner of the casing wall-retainers

(not yet screwed down)

Completed wall retainers

(bolts yet to be cut off flush)

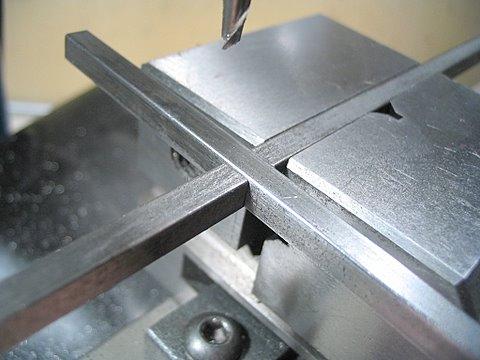

Cutting the cheeks to create cross lap joints in the front plate stiffening bars

Checking the cross lap joint fit

Front plate mocked-up

Stack material will be made from this piece of thinwall

steel electrical conduit

Checking casing wall retainer height for parallelism on a

granite surface plate

(prior to silver brazing the steel angle to the boiler

casing's front plate)

The retainers are only screwed (not brazed) to the skid and will be easily

removable

A small length of the retainer silver-brazed to plate

Dremel disk (black circle) cutting through after chain-drilling for steam drum opening

( - those

are sparks, not scratches to the left! )

The end of a dirty job!

Same opening after filing smooth

(this opening will be covered by a round plate, leaving an identical-sized

hole to the lower drum access hole)

Just 3 more sides, 4 roof sections, a burner unit

and the pressure vessel to go!

Note that the bottom of the lower

drum access hole

has been cut into the red oxide skid assembly,

as per the prototype

The opening on the right is the burner

firehole

The rectangular boiler flue gas outlet is

marked out on the side wall

Flue outlet cut out - yet to have the stack duct attaching flange

added

This is hard to understand from

pictures:

The front and back plates lap over the skid, while the side walls simply butt against the floor of the skid. There is a reason - inside access for inspection will be provided by lifting the complete roof and side walls in one piece upward from between the front and back plates. Note there is a small reveal of those plate's edges past the side walls..

As the project progresses a matching base trim strip at the bottom of all walls and thin batons reinforcing the side walls will be added to resemble the prototype. Actually the prototypes use small T-bars on the sides, but in proper scale they would be very fragile for a working unit of this size.

Inside retainer strip keeps the wall (and ceiling

eventually) from going in too far

(The main purpose is to provide a seal against air

leaks

into the enclosure which would destroy the draft)

Starting fabrication of the roof

My plan is to edge-braze the pieces with Easy-flo

45

Yeah, ok - I got away with it...

Better than expected

The shed roof section on the right will be silver

brazed in

situ

(the shed roof piece on the right actually overhangs the wall - that's a pencil line on the roof, not the top edge of the right wall)

Checking that the four corners are in one plane on a granite surface block

Now it's time to join walls and roof

Now it's time to join walls and roof (along the white seam)

Chopin' up some silver brazing alloy

Ready to go

After the heating

Easy-flo 45 has flashed into the joint

beautifully -

Easy-flo 45 has flashed into the joint

beautifully -

Hooray for propane gas and a four-dollar torch!

These last shots show how the boiler casing looked

as of Dec 16, 2008.

There is still quite a bit of cleanup and trim work to be completed...also a couple more openings at the back and flanges to be fitted. The entire inside surface of the enclosure will be lined with shiny aluminum tape, covered by a one-half-inch layer of high temperature thermal blanket insulation. There are holes needed for various connections to the upper steam drum (upper one) - such as water gauge glass, pressure gauge, feedwater inlet, blowdown outlet and on the top - two safety valves, a main steam outlet, vent valve etc..

The copper pressure vessel components will be started in the

New Year (2009) after I have time for a good clear run at them. I

am looking for a 1/2" phosphor bronze rod to make the threaded bushes for the

drum. People in my area tend to throw up their hands and say "what is

phosphor bronze?" Gunmetal which is also suitable for this purpose is unheard of in North America.

There is Commercial Bronze - no good, as it

contains too much zinc, there are machining bronzes which contain lead, but Phosphor

Bronze A, B or C are almost "pure bronze" - copper and tin. They will not

disintegrate in a model boiler like many of the brassy bronzes.